The Difference Between Overhead and Magnetic Stirrers

In laboratories, overhead and magnetic stirrers are commonly used to agitate liquids and semi-liquids to speed up or enhance a reaction or cell culture. Although both types of stirrers perform the same stirring function, each has advantages and disadvantages.

This article discusses the differences between overhead and magnetic stirrers and how their components can better suit specific situations.

Overhead Stirrers

Overhead stirrers are an essential tool for many industries that require precise mixing of viscous substances. With their efficient design and versatility, overhead stirrers are an effective solution for mixing large volumes or viscous liquids and semi-liquids.

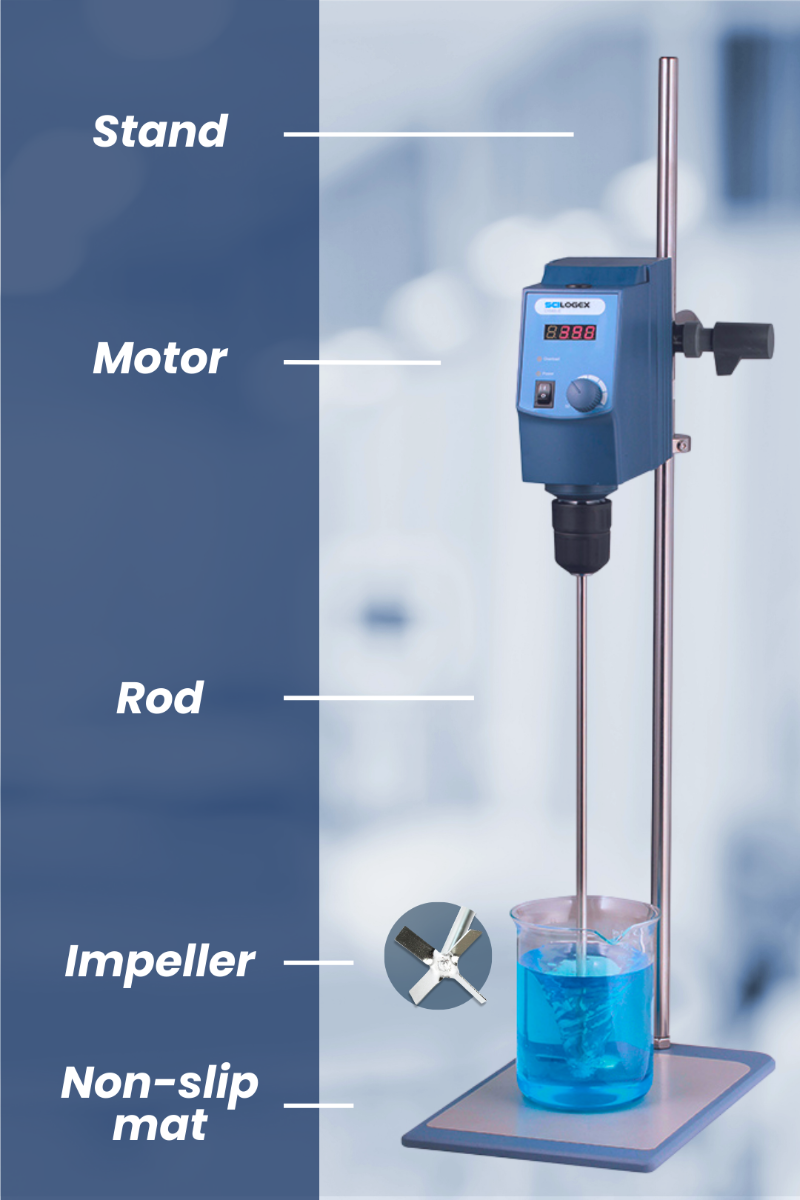

Each overhead stirrer comprises a motor, various impellers, a rod, a non-slip mat, and a stand. The motor provides the necessary power to turn the impellers, which churns the substances. The rod connects the motor to the impellers, while the non-slip mat provides stability and prevents the vessel from slipping and jostling. The stand supports the motor and can be adjusted to the correct height needed for mixing.

These features of an overhead stirrer make them a popular choice for various industries. Commercial food laboratories use large-scale overhead mixers to mix large volumes of ingredients. In contrast, smaller-scale mixers are popular in chemistry, biology, and analytical laboratories to prepare samples for analysis. Yet, these smaller-scale overhead mixers have the ability to mix 20-40L of liquid.

Impellers

Each impeller plays a unique role and creates various flow patterns:

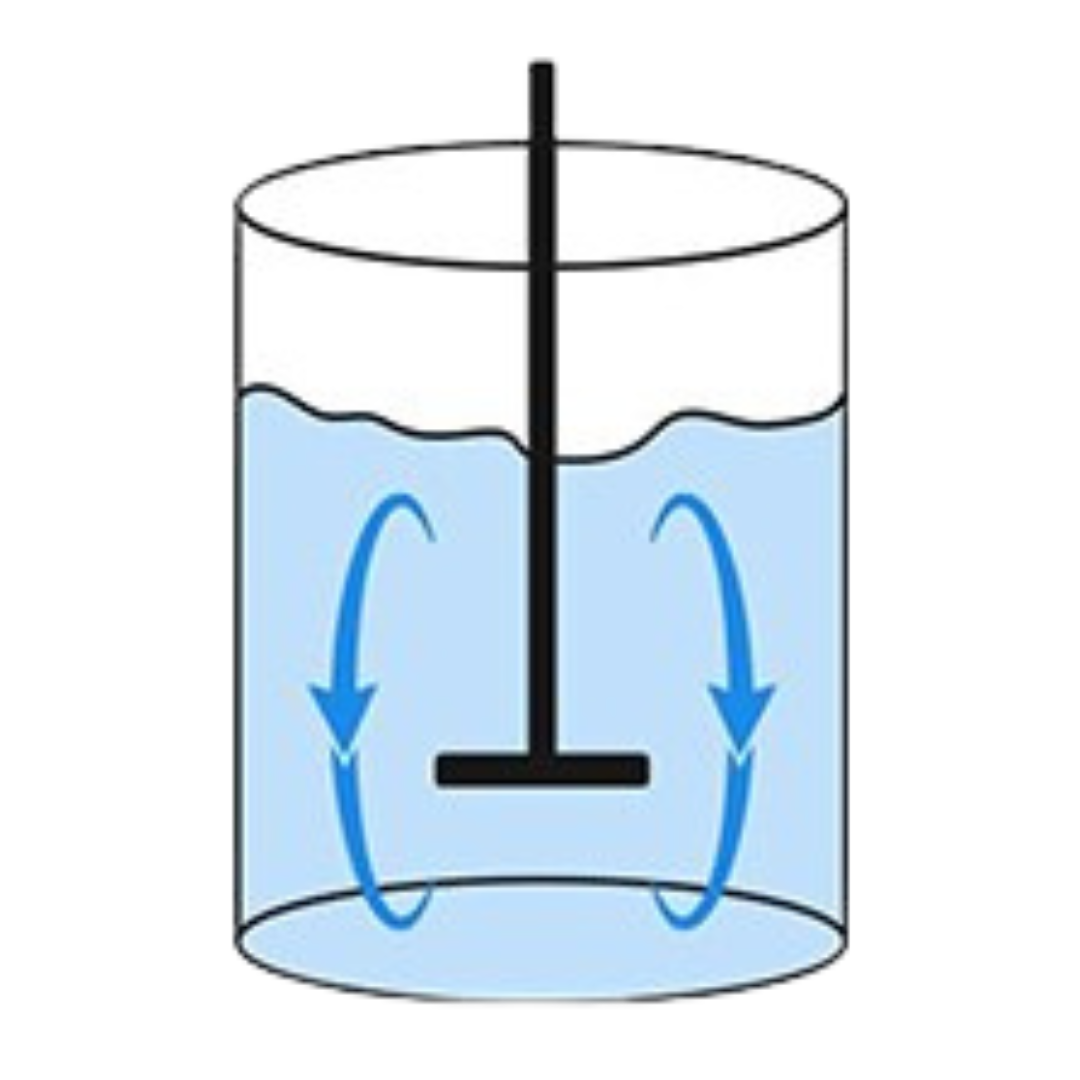

Axial Flow

Axial flow is where liquid moves vertically from the bottom to the top of the vessel.

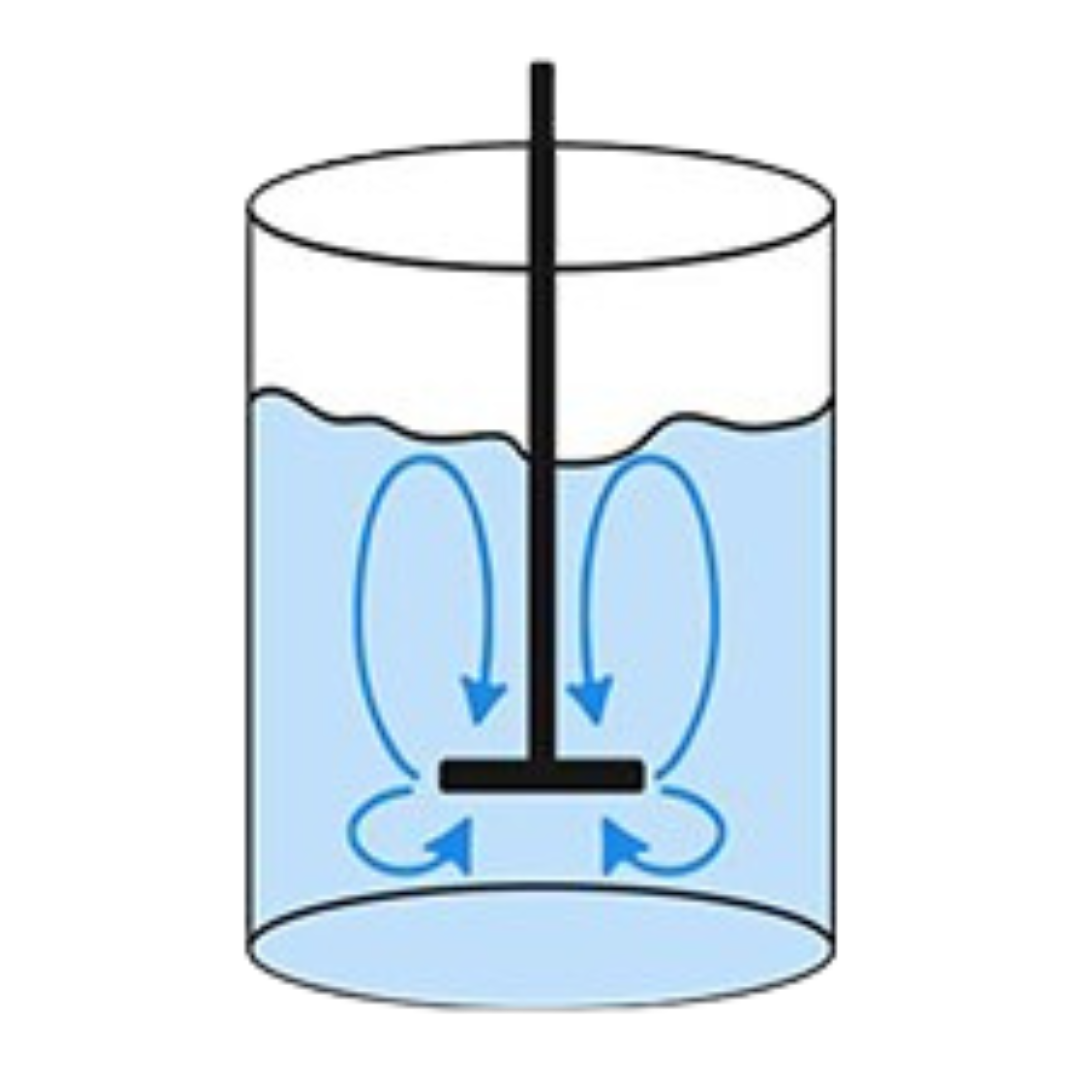

Radial Flow

Radial flow is where liquid moves horizontally and then vertically before flowing back toward the center of the vessel, where the impeller is churning.

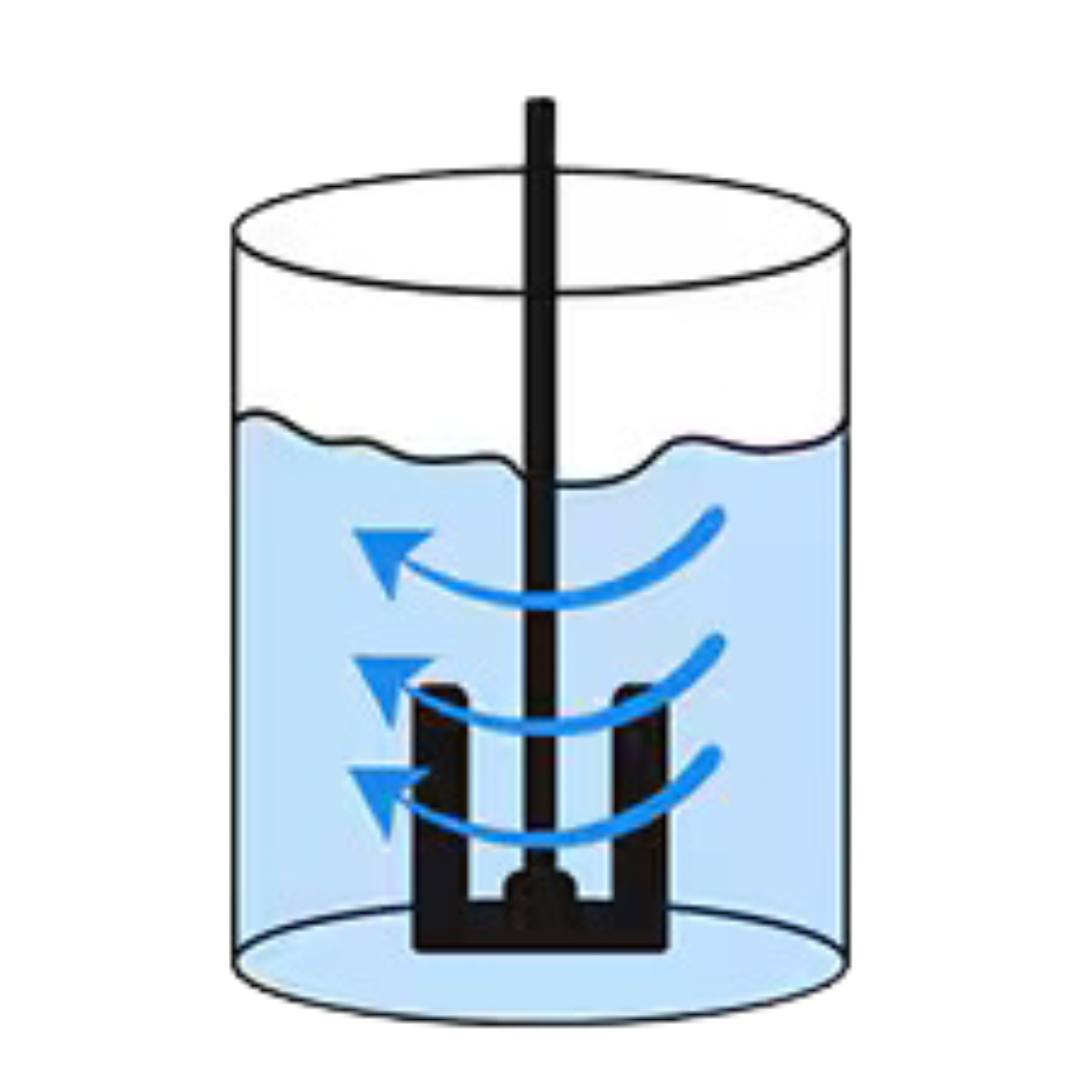

Tangential Flow

Tangential flow is where liquid moves around the vessel horizontally with little vertical flow.

Image credit to Thermo Fisher

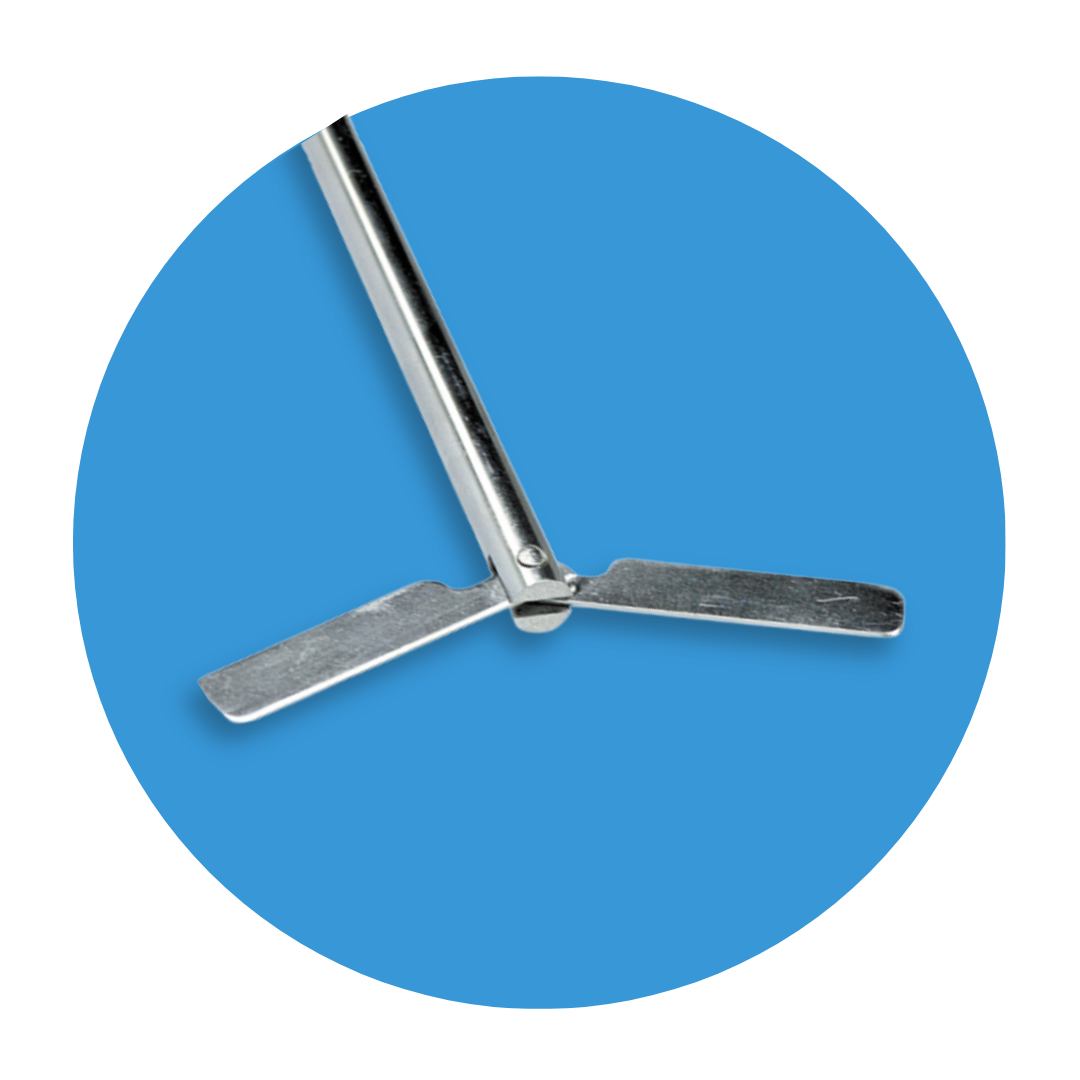

Propeller

Propellers are commonly used in applications requiring medium to high-speed stirring in large volumes or where the fluid or semi-fluid material is medium to highly viscous. These stirrers create an axial flow with either an X or Y shape. Propellers are also helpful for homogenizing or suspending properties in the material.

Turbine

Turbines, also called rings, are impellers best suited for gassing and dispersing low-to-medium-viscosity liquids at an average speed. They churn liquids using a radial flow.

Anchor

Anchors are impellers that use tangential flow and are more optimal for low speeds with a medium-viscosity substance.

Paddle

Paddles are wide impellers designed for more gentle stirring and mixing. They are ideal for low to medium speeds and create a tangential flow. A paddle impeller is ideal for use in low-viscosity liquids.

Straight

Straight impellers utilize radial flow to create a vortex within their vessels. They are excellent tools for mixing low-viscosity liquids at high speeds.

Dissolver

Dissolvers are known for their unique shape and bladed tips. They utilize radial flow to mix medium to high-viscosity materials at a medium- to high speed, excelling at homogenization and suspensions.

Dispersion

This sawtooth-like impeller provides a high shear, dispersing or transporting a one-phase material or ingredient into a continuous phase. The dispersion’s teeth break down agglomerations for dispersion, hence the name. It does this using a radial flow.

Centrifugal

Also known as collapsible impellers, centrifugal impellers mix at medium to high speeds and are recommended for vessels with narrow necks.

Impellers can be made of stainless steel, glass, other metals, or coated PTFE. Although stainless steel is the most commonly used material, PTFE may be preferable for more corrosive materials and acids.

Magnetic Stirrers

Magnetic stirrers can be found in almost every laboratory that requires stirring liquids. Using an electric mortar, magnetic stirrers churn liquids employing a magnetic field to spin stir bars within a vessel. Most magnetic stirrers are optimal for non-viscous substances and lower volumes. However, this may vary based on the power of the stirrer and the type of stir bar used.

Magnetic stirrers are available in both analog and digital versions, and some models come with a hot plate for heating and stirring applications. To avoid any interference with the magnetic field of the stirrer, it is recommended to use glass vials and beakers.

Stir Bars

Here are some of the more popular stir bars:

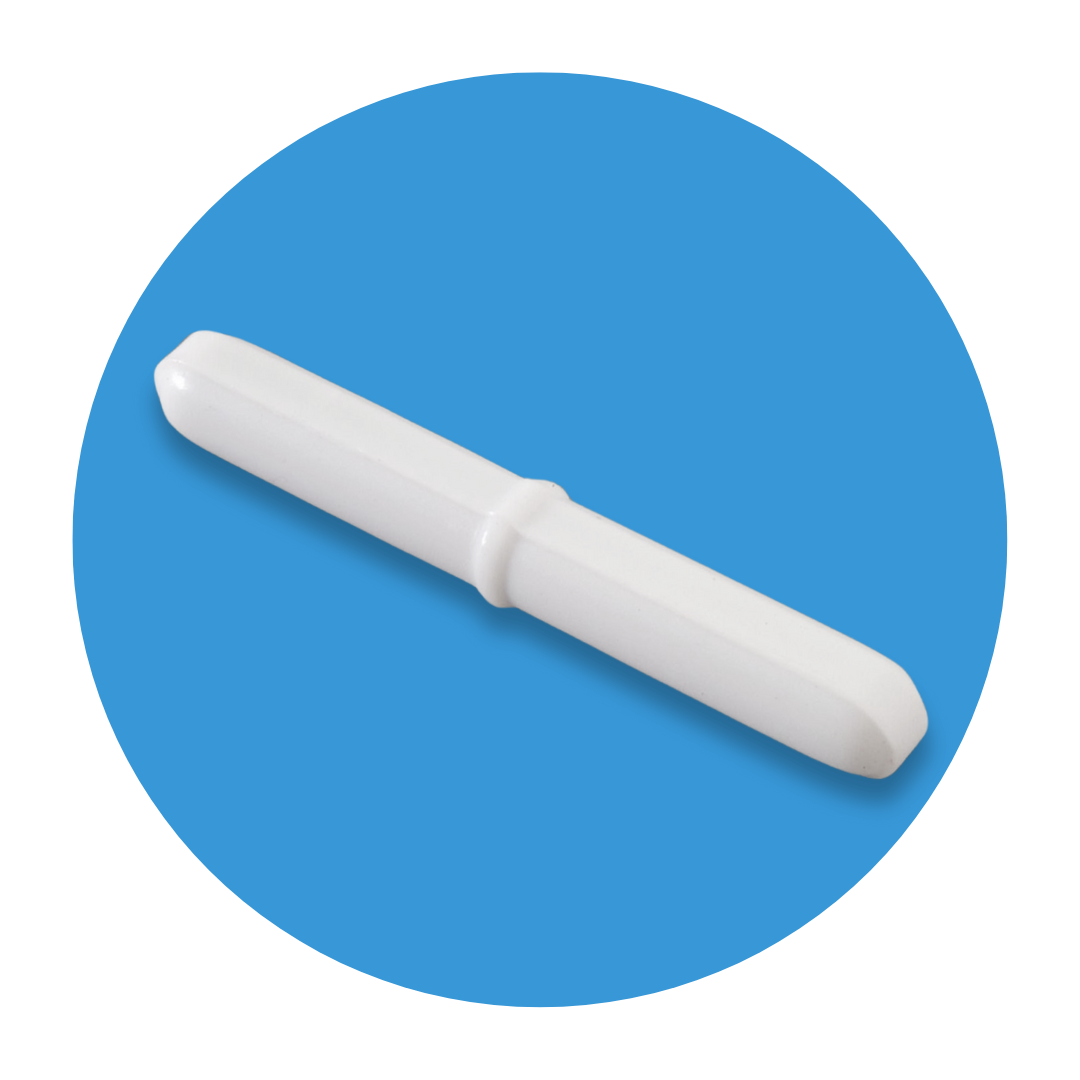

Polygon and Octogon Stir Bars

Polygon and Octogon sir bars have smooth multi-face surfaces, and thanks to their center pivot rings, they efficiently reduce friction between the vessel and the bar. These stir bars are also available without pivot rings.

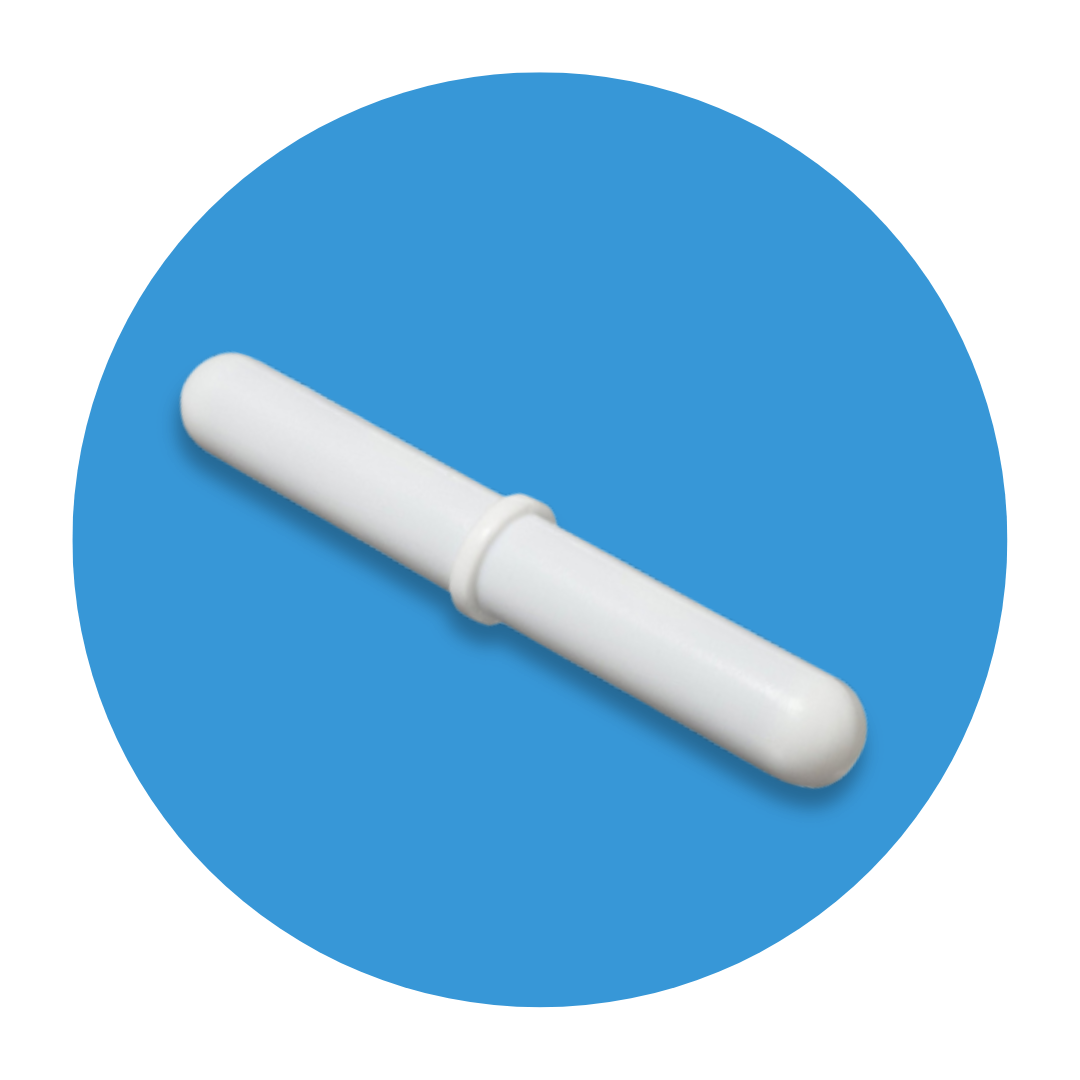

Oval/Egg/Ellipse Stir Bar

The oval stir bars are optimal for homogeneous mixing in round-bottomed beakers and flasks.

Cross Stir Bar

Cross-stir bars excel at high-speed stirring and creating turbulence for stirring. It can also be used to churn sedimentation.

Crown/Crosshead Stir Bar

Crown stir bars are ideal for greater mixing action at a vessel's bottom, top, and sides. They are suitable for cuvette and test tubes.

Prism Stir Bar

Prism stir bars are highly effective in creating turbulence, regardless of the speed setting. They are ideal for preventing sedimentation and promoting dissolution as they scrape the bottom of the vessel while spinning. This type of stir bar is considered the most efficient and effective for laboratory applications.

Round Stir Bar

Ideal for use with flat-bottomed beakers and flasks, round stir bars are suitable for a variety of applications. Some round bars are smooth, while others come with a pivot ring.

The stir bars come in various shapes and sizes. They are typically coated in Teflon® or glass to prevent contamination or a reaction with the chemicals, as these coatings are chemically inert and autoclavable. They may also come in a PTFE coating for single use or other applications.

When to Use Which

There are multiple things to consider before selecting a stirrer for your application:

| Overhead Stirrer | Magnetic Stirrer | |

|---|---|---|

Volume |

Suitable for large volumes with the ability to upscale |

Ideal for lower volumes with an inability to upscale |

Viscosity |

Impellers allow for mixing more viscous materials and can handle changes in viscosity over time |

Stir bars are not able to stir in more viscous liquids |

Vessel shape |

Difficulty fitting in impellers for narrow neck vessels |

Operator can quickly drop in and retrieve a stir bar from a narrow-neck vessel |

Types of stirring |

Impellers allow for additional flexibility |

Ideal for mixing and blending liquids, dissolving powder, and churning sedimentation |

Shear |

Can vary from low to high shear based on the impeller used |

Low shear |

Costs |

Are usually more expensive |

Less costly overall |

We hope you have found this overhead and magnetic stirrer breakdown helpful. If you are interested in buying your own overhead or magnetic stirrer, shop Scilogex, who strives to offer the most uniquely innovative laboratory tools for all areas of scientific research. If you have questions, contact our expert team at 1-800-733-2522, [email protected], or message us via Live Chat, available on our website.