Flow Rate and Throughput

Flow rate and Throughput are related measurements of filter media and device performance affected by several other properties. The primary determinants of these values are:

Water Flow Rate

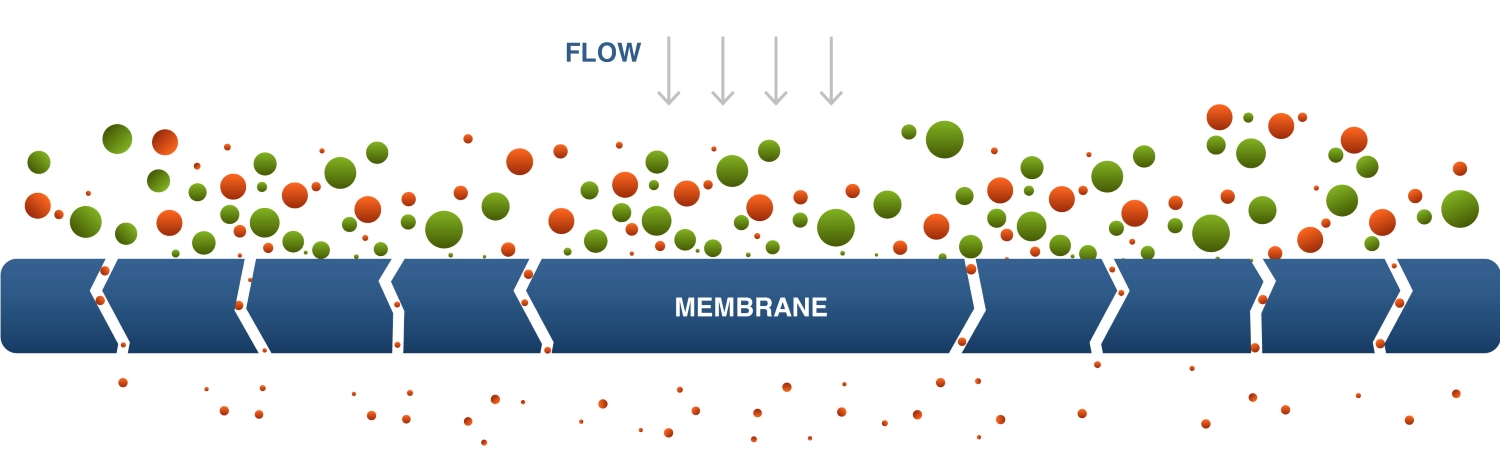

Water flow rate measures the amount of water that flows through a filter, commonly expressed in milliliters/minute (mL/min), at a given pressure. It is influenced by the degree of contamination, differential pressure, total porosity, and the filter’s effective filtration area.

Air Flow Rate

Air flow rate measures the amount of air that flows through a filter, commonly expressed in liters/minute (L/min) at a given pressure. It is also influenced by the degree of contamination, differential pressure, total porosity, and the filter’s effective filtration area.

Throughput

Throughput is the amount of a sample that passes through a filter.

Differential Pressure (ΔP)

Differential pressure (ΔP) is the difference between the upstream and downstream pressure in the system. It is the difference in pressure measurements taken before the fluid reaches the filter and after the fluid flows through the filter. Differential pressure increases as the filter begins to clog in continuous flow applications.

Viscosity

Viscosity measures a fluid’s resistance to flow. High viscosity (at a constant temperature and pressure) lowers the flow rate through a filter (assuming viscosity remains constant).

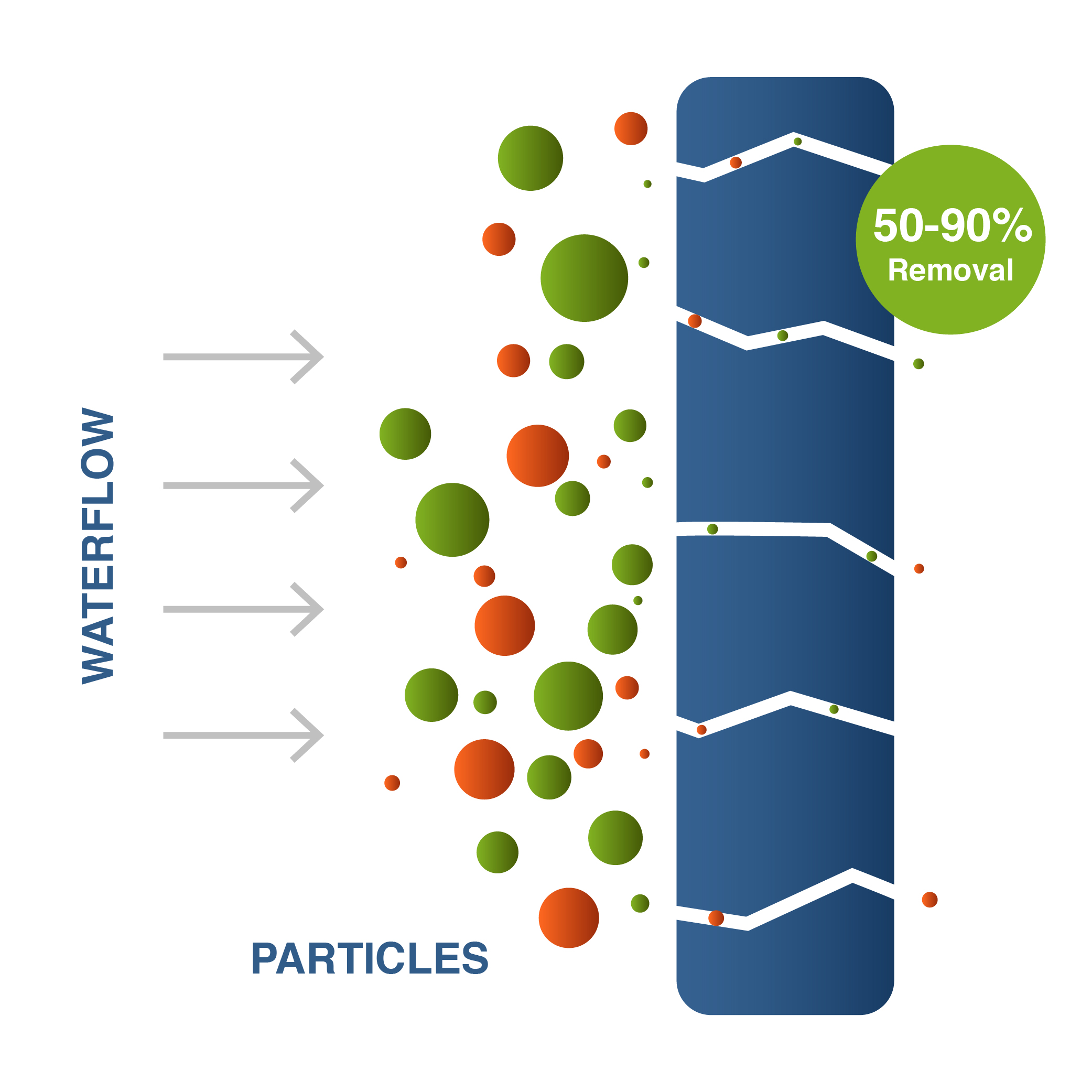

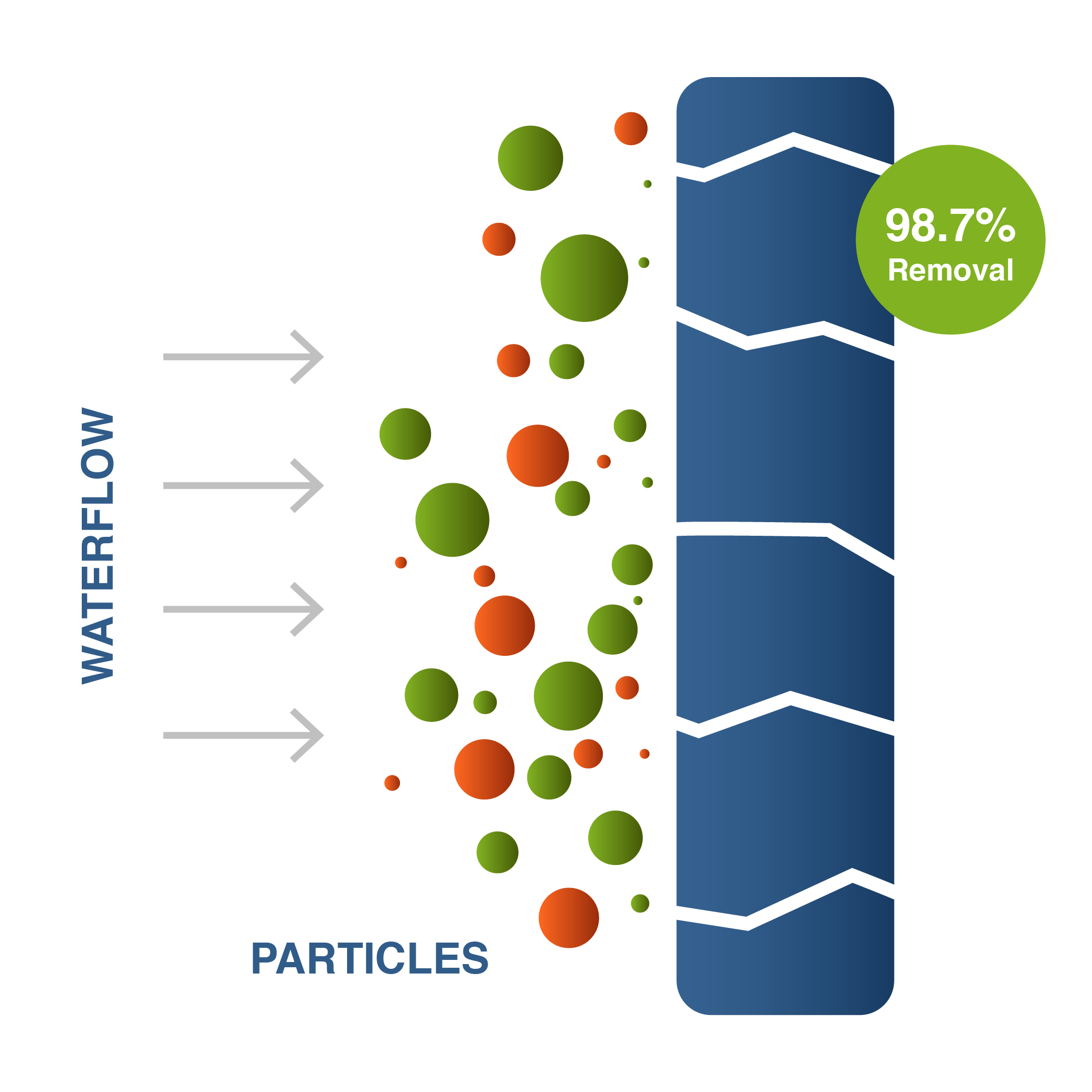

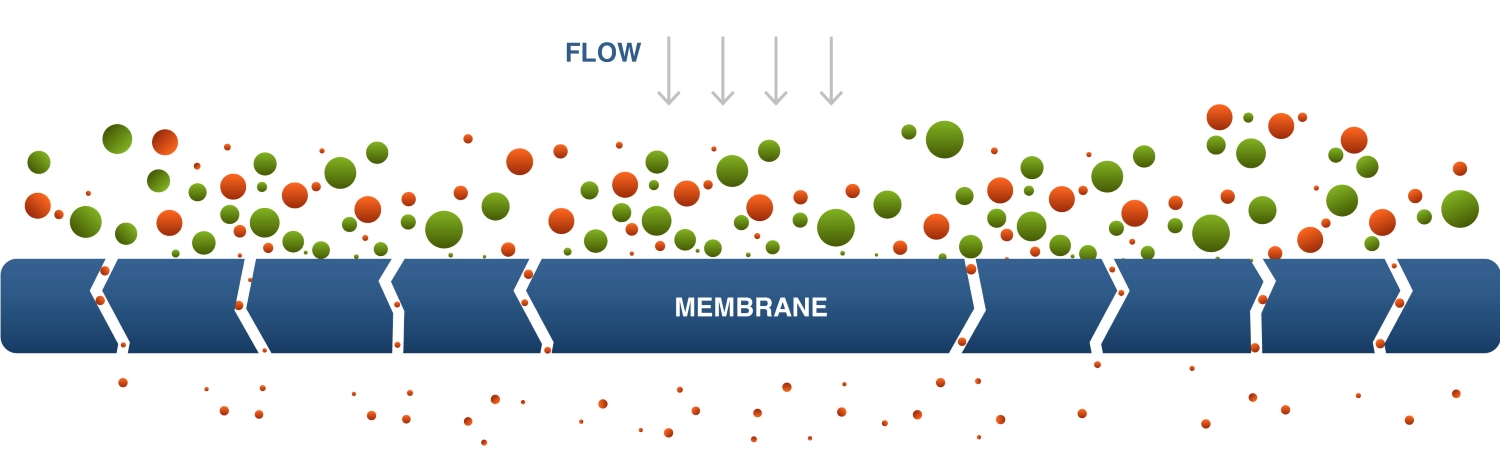

Porosity

Porosity (“open area” or “void volume”) measures open spaces (pores) in the membrane as a percentage of the total membrane area. Generally, membranes have 50-90% open space, and flow varies in direct proportion to membrane porosity.

Effective Filtration Area (EFA)

Effective filtration area (EFA) is the filter area available for filtration; for a specific membrane, flow rates are higher (at a given differential pressure) for larger EFAs.

Filter Media and Device Configurations

Filter media and device configurations include a vast array of sizes and configurations. Options range from disc membranes to small syringe filters to large capsule filters.

Disposable Filter Devices

Disposable filter devices are intended for single-use applications and provide a convenient means of filtering various sample volumes. These devices are often pre-sterilized and include “ready for use” syringe filters and capsule filters that consist of a membrane integrally sealed into a polymeric housing with fittings for easy attachment to syringes, tubing, or piping on the inlet and outlet of the device.

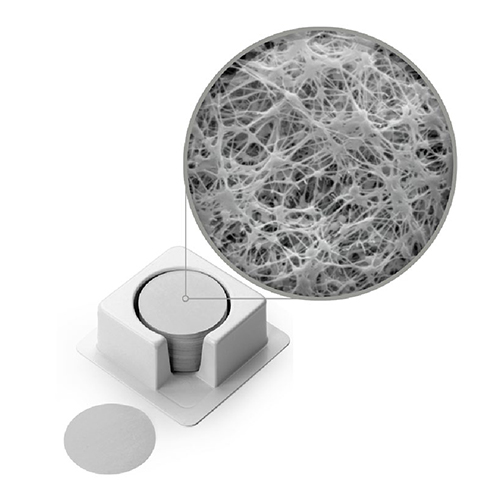

Disc Filters

Disc filters are economical, pre-cut filters that the end user can integrate into a reusable filter holder (made of stainless steel, glass, or polymeric housing material). Note that some applications may require the end-user to sterilize the filtration system before use.