Understanding Directional Airflow of Ductless Fume Hoods

Ductless fume hoods have become a staple in many laboratories because of their cost savings, mobility, reliability, and, most importantly, their ability to protect users and samples. Despite their popularity, the industry’s knowledge regarding these fume hoods is unclear, especially information about airflow.

This article aims to provide a detailed overview of the basics of airflow, the different types of airflow, and their applications. By the end of this article, readers will better understand ductless fume hoods and their airflow capabilities, leading to informed decisions on their suitability for their laboratory needs.

Before We Go Further

Before we go further, it is necessary to understand the two types of airflow that ductless fume hoods can provide. The two types are positive and negative displacement airflow and are suited for different applications and sample needs.

It is essential to understand these differences to determine whether you aim to retain contaminants within the fume hood for filtration, primarily to safeguard the operator, or expel potential contaminants from the fume hood to protect the samples.

Positive Displacement

Positive displacement airflow units are specifically designed for ISO Class 5 Cleanrooms. These units filter the air and create a positive pressure in the work area. This helps protect the samples from contamination while being handled under the hood or when multiple samples are at risk of cross-contamination. There are two types of displacement airflow: horizontal and vertical.

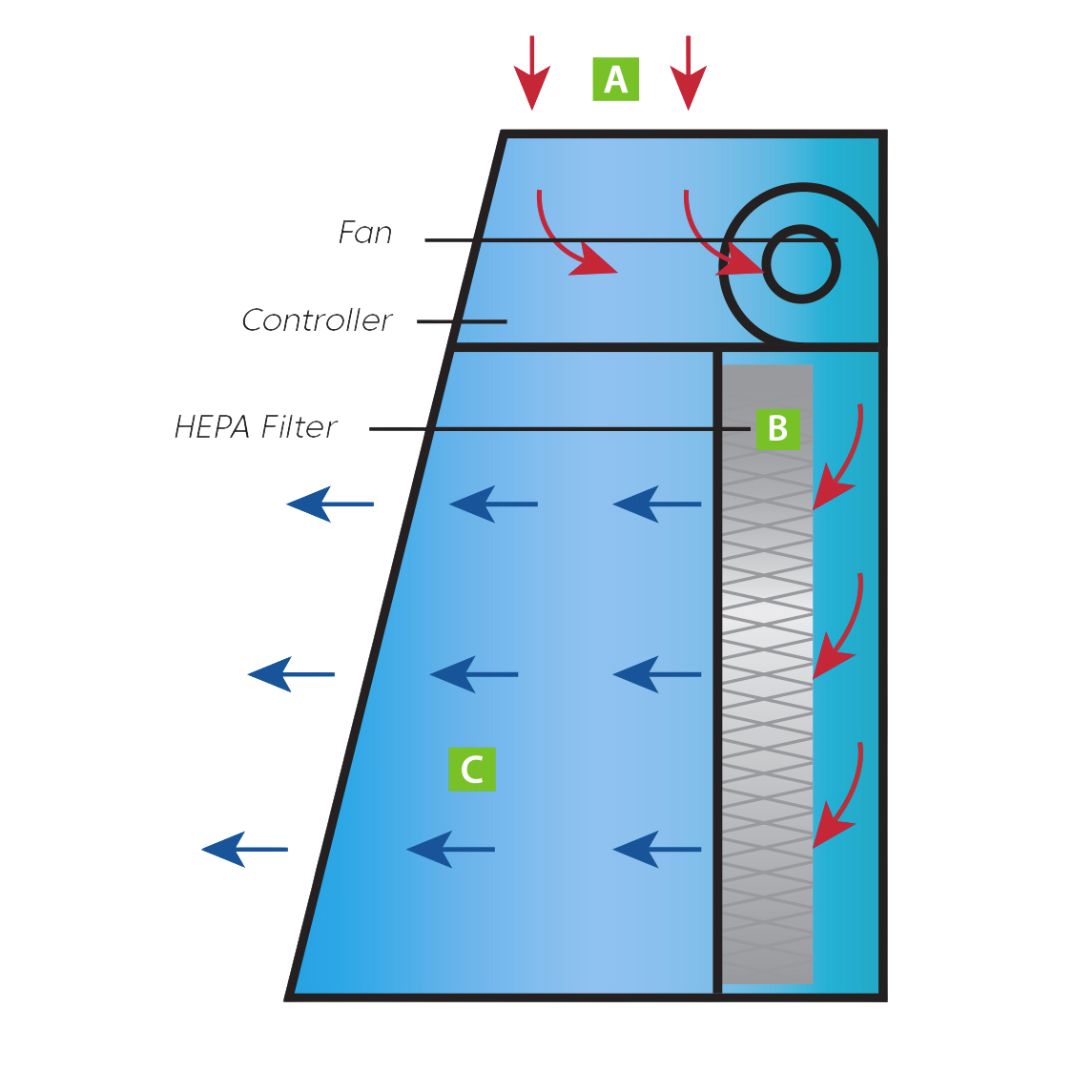

Horizontal Airflow

With horizontal laminar flow hoods, air enters through the filter(s) at the top of the unit, pushes the air downward and then horizontally across the workbench, and exits through the opening below the sash. Horizontal airflow directly protects the samples by using filtered air to combat particle contamination generated on or above the work surface as the user handles the samples.

Applications using a horizontal laminar flow unit include medical compounding, IV therapy, IVF, small electronic assembly or examination, cell/tissue cultures, media culture preparation, thin film deposition, and more. Exercise caution when using large equipment inside horizontal flow units, as it can disrupt airflow and lead to contamination from unobstructed airflow.

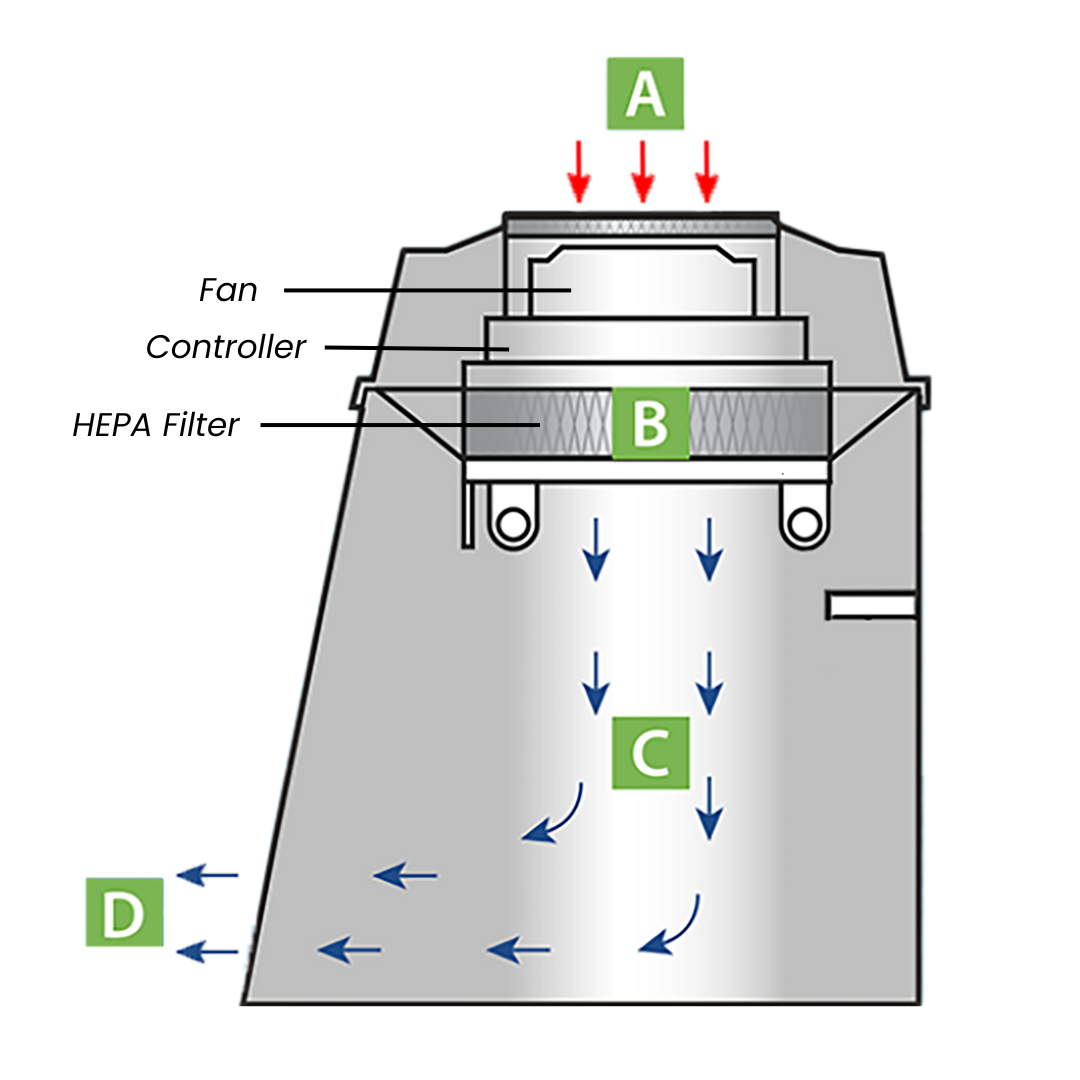

Vertical Airflow

Vertical laminar flow hoods, also called “downflow” hoods, filter air from the top of the unit down toward the work surface, creating a waterfall effect. This downflow of air utilizes high turbulence to reduce cross-contamination from other samples within the hood. It also works well if long, large, or girthy equipment is needed under the hood.

The units that utilize vertical airflow are vertical laminar flow units and PCR hoods. Applications for vertical laminar flow hoods include preventing cross-contamination of powders, microbiological samples, large electronic assembly and examination, and chemical reactions that are considered non-hazardous.

PCR hoods and enclosures can perform similar functions to vertical laminar flow hoods. However, their built-in UV lights decontaminate the worksurface, allowing for DNA and RNA applications and manipulations.

Dangers of Positive Displacement Fume Hoods

It is important to note that these units are designed for process protection only. Contaminates will be blown toward the operator to protect the sample. Therefore, horizontal and vertical flow units are not recommended for working with hazardous or flammable materials as they could put the user at risk.

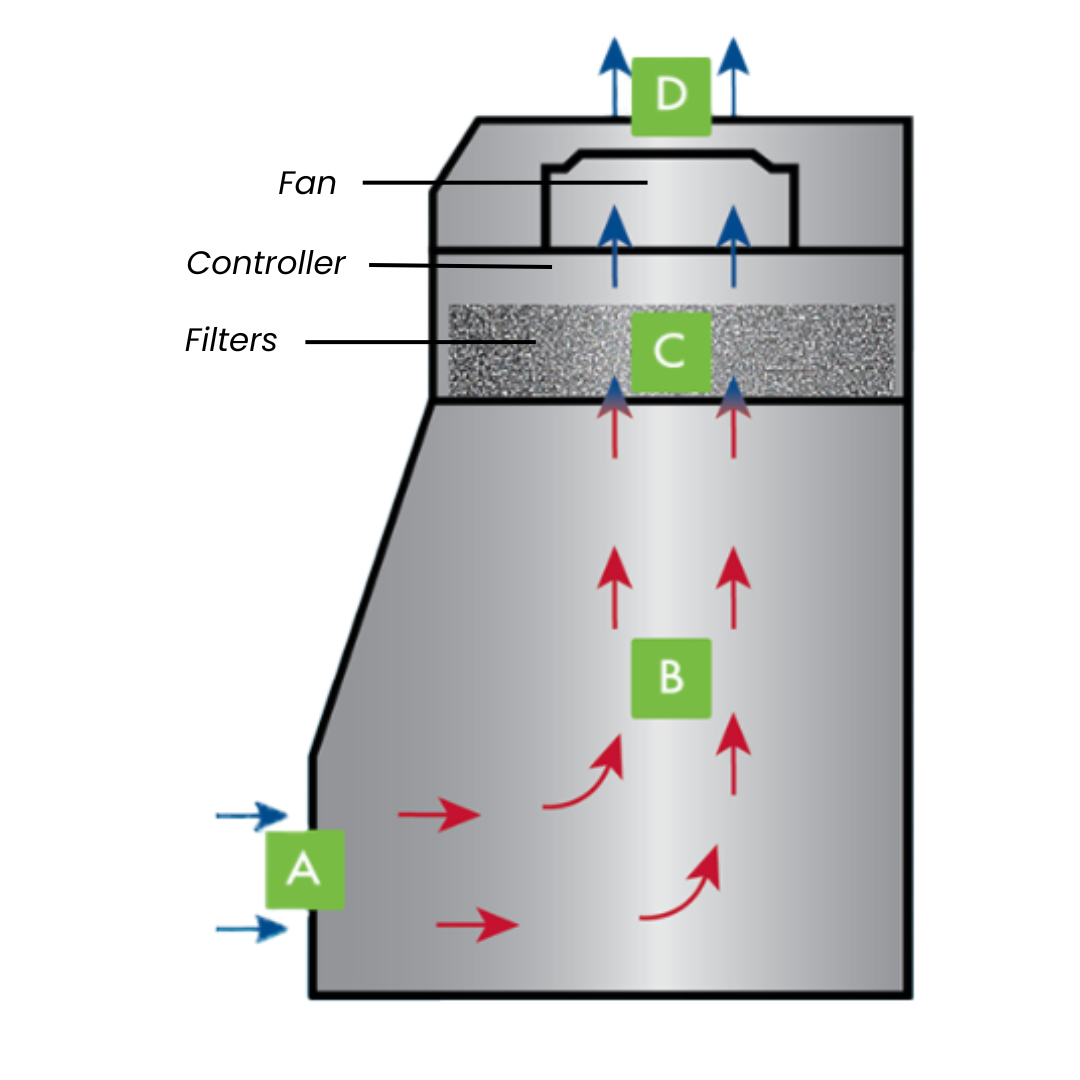

Negative Displacement

In contrast to horizontal and vertical airflow units, negative displacement fume hoods operate based on negative pressure. These negative-pressure fume hoods minimize exposure of harmful airborne pollutants and contaminants to the operator’s breathing area. These hazardous contaminants include airborne contaminants, particles, and chemical fumes.

These units actively draw air through the sash, exposing it to hazardous gases or particles produced by the samples. Subsequently, the fume hood filters the air using a prefilter, HEPA, carbon, and other filter types to purify it. Depending on the unit type, the purified air is reintroduced into the laboratory or recirculated back into the fume hood.

Negative pressure fume hoods are frequently used in various settings, including chemistry laboratories, dental laboratories (particularly for tasks such as denture grinding), and other biological applications where harmful particles, VOCs, and similar substances are a concern.

A special thanks to Mystaire Inc., who took the time to peer review our article to ensure accurate information and supplied the graphics seen in the article. We hope this article has given you valuable insight into the various types of airflow utilized by fume hoods. For any additional questions about fume hoods, read our article The Different Types of Ductless Hoods to learn more. We also have an excellent customer support team here to help you in your purchasing decision. Call 1-800-733-2522, Email, or message us via Live Chat, available on our website.

Sources:

https://www.airscience.com/laminar-flow-hood-vs-ductless-fume-hood

https://www.airscience.com/pcr-workstation-dead-air-vs-laminar-flow

https://www.besttechnologyinc.com/wet-bench/what-is-a-fume-hood-how-do-fume-hoods-work/

https://www.mystaire.com/news/filtered-or-ductless

https://www.mystaire.com/news/new-generation-laboratory-safety-filtered-fume-enclosures

https://www.nationallaboratorysales.com/blog/what-is-a-fume-hood-sash/

https://www.ossila.com/pages/laminar-flow-hoods-vertical-vs-horizontal