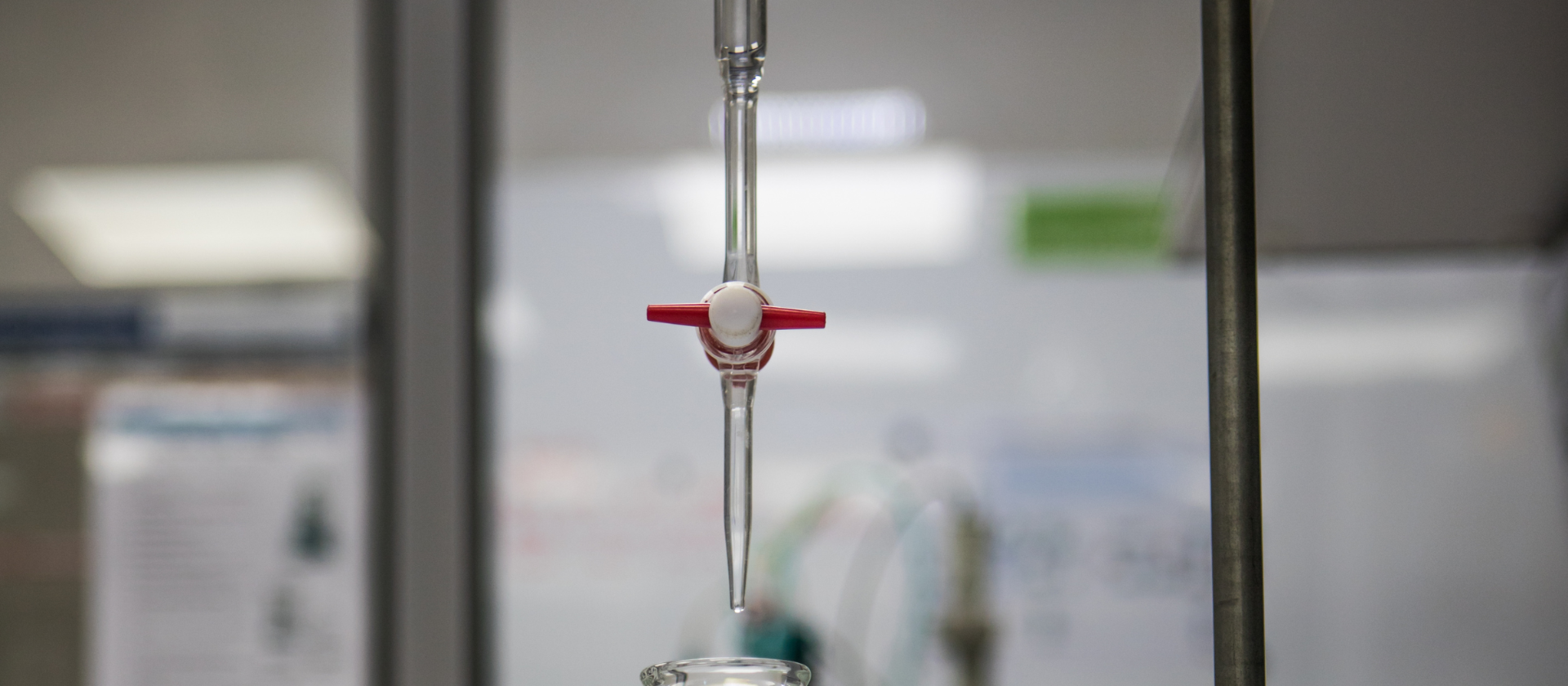

Care and Use for Stopcocks with PTFE Plugs

Kimble PTFE stopcock plugs are made of the most chemically inert material in laboratory use today. Only a few chemicals have any effect on PTFE and only at elevated temperatures and pressures. The material is extremely tough, durable and heat resistant, with practically zero moisture absorption. It remains non-brittle even at sub-zero temperatures. Observe the following hints to obtain maximum performance from your PTFE stopcock plugs:

1. To clean new plugs, carefully disassemble, lift plug free of glass barrel, and rinse all parts of plug and barrel in acetone. After drying, reassemble, and the stopcock is ready for use (do not use abrasive materials to clean either plug or barrel at any time.)

2. The washer of PTFE must always be placed adjacent to the end of the glass barrel to secure minimal friction when turning. When properly tightened, the plug will be slightly more resistant to turning than a lubricated glass plug.

3. Plugs of PTFE can be easily scored around the bore if rotated when solid particles are lodged between plug and barrel or

project beyond mating edges of glass parts. Once scored, the plug may leak.

4. Do not use a stopcock plug of PTFE on a vessel used for long time storage of liquids known to attack glass since the surface of the barrel may become roughened, and leakage may occur between the plug and barrel, causing a potential safety hazard.

5. If plugs of PTFE are used with liquids corrosive to glass, such as alkalies, rinse the stopcock thoroughly with water after use. Do not allow the liquid to evaporate. The concentrated solution remaining will attack the glass surface and the eventual solids may also mar the surface of PTFE if the plug is then rotated.

6. When not in use, store in a dust-free area with the plug loosened within the glass barrel. Although tough and unbreakable, PTFE is softer than glass and has a tendency to conform to the glass surface, including eventual expansion into the hollow parts of the barrel.

Information courtesy of Kimble-Chase

Kimble PTFE stopcock plugs are made of the most chemically inert material in laboratory use today. Only a few chemicals have any effect on PTFE (Polytetrafluoroethylene), and only at elevated temperatures and pressures. The material is extremely tough, durable, and heat resistant, with practically zero moisture absorption. It remains non-brittle even at sub-zero temperatures.

Obtaining Performance for PTFE Stopcock Plugs

To obtain maximum performance from your PTFE stopcock plugs, use the following care and use:

1. To clean new plugs, carefully disassemble, lift the plug free of the glass barrel, and rinse all parts of the plug and barrel in acetone. After drying, reassemble, and the stopcock is ready for use (do not use abrasive materials to clean either the plug or the barrel at any time.)

2. The PTFE washer must always be placed adjacent to the end of the glass barrel to secure minimal friction when turning. When properly tightened, the plug will be slightly more resistant to turning than a lubricated glass plug.

3. PTFE plugs can be easily scored around the bore if rotated when solid particles are lodged between the plug and the barrel or project beyond the mating edges of glass parts. Once scored, the plug may leak.

4. Do not use a stopcock PTFE plug on a vessel used for long-time storage of liquids known to attack glass since the surface of the barrel may become roughened, and leakage may occur between the plug and barrel, causing a potential safety hazard.

5. If PTFE plugs are used with liquids corrosive to glass, such as alkalies, rinse the stopcock thoroughly with water after use. Do not allow the liquid to evaporate. The concentrated solution remaining will attack the glass surface, and the eventual solids may also mar the surface of PTFE if the plug is then rotated.

6. When not in use, store in a dust-free area with the plug loosened within the glass barrel. Although tough and unbreakable, PTFE is softer than glass and has a tendency to conform to the glass surface, including eventual expansion into the hollow parts of the barrel.

Sources:

Information courtesy of DWK Sciences.